Birchington

Heritage Trust - Newsletter

Birchington

Heritage Trust - Newsletter  Birchington

Heritage Trust - Newsletter

Birchington

Heritage Trust - Newsletter |

Building

with

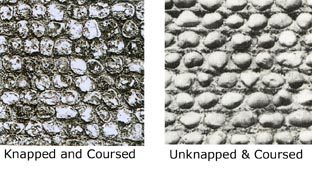

Flint Britain is the only country in the world where flint was frequently used in buildings. It is found in the upper and middle layers of chalk and began life as a liquid. It is harder than quartz and is one of the purest forms of silica. It was the first material to be mined in Britain and some 60,000 flint tools and weapons, some nearly 100,000 years old, have been found in Kent. The shore between just east of Reculver to Whitstable is rich in flint pebbles. Flint has been used for building since Roman times, with Richborough Castle being a good example locally. The Romans used it for their roads, which is one of the reasons they stood up to the heavy wear of the Legions. When used in buildings, the unknapped (or natural) flints needed a lot of mortar to hold them together. To reduce this problem, men began knapping the flints, by chipping off the rounded edges.  In Kent flint has

always been

readily

available with very little effort and there are plenty of flints in

local

gardens. Many of the pebbles on the beaches of Birchington are flint

and there

are bands of flint visible in the cliff faces as you walk along the

promenades. Farmers often

encouraged

the parishes to send flint-gatherers onto their land to help dear the

pebbles,

as they interfered with ploughing.

These pebbles were then used in road repairs, a task

which still came

under the care of individual parishes until late in the 19th

century. FLINT MILLS Flints were so

abundant in

Thanet, they

became a vital export commodity. The counties of Kent and Sussex sent

flints to

Staffordshire by canal for grinding.

The flint mills at Cheddleton in Staffordshire

ground up the flint into

a fine powder to be used in the nearby Potteries.

The output from Cheddleton Mills was used in the

Minton works at

Stoke-on Trent. The flints were unloaded straight into the mills, where they were heated in huge kilns for three days until they became brittle. They were then immersed in water, causing them to crack into small pieces, which were then crushed in the mill. This saved the workers' lungs from the lethal dust of the early years, when much of this work was done by hand in a process called dry-crushing. The creamy slurry in the grinding pan was mixed with water and put in a settling tank, where the flint powder sank to the bottom to form a thick sediment. When dried, it was cut into blocks and dispatched to the potteries, where it was used to strengthen certain clays and also in the glazing processes.

Looking round the village, we can still see a number of buildings which contain this mineral, notably All Saints Church in the Square. These walls were once covered with a rough lime rendering, which is visible in an old photograph of about 1860. The Victorians cleaned this off and repaired the walls in 1863 to what we see today. Some other examples of flint nearby are found in the churchyard walls, the cottages opposite and the cottages on the comer of Canterbury Road and Kent Gardens as well as the aptly named ones in Mill Row (see photograph). There is also a terrace in Epple Road with flint walls at the back of the properties and there used to be a flint cottage on the comer of Park Avenue and another by the village pond, until Margate Borough Council decided to widen the Canterbury Road in 1933. |